/ = agricultural machinery, equipment, equipment, equipment (Equipment) / Харчова промисловість (обладнання)/ flour mill and large equipment / = Industrial Equipment for thin grinding in flour ...

Продам / купити

Industrial Equipment for thin grinding in flour, 500 kg. Dispersion, Chernivtsi region

price 50 000 €

Регіон: all Ukraine,

Chernivtsi Region 10: 25

Оновлено:

company Bioecope GC - modern technologies of grinding and grinding

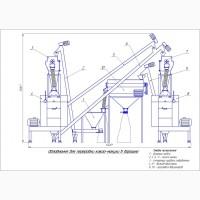

= Bioecope GC offers innovative industrial equipment for high -precision grinding and grinding raw materials into flour and powders. Our unique solution "Dispersion" is a complex of equipment that provides differential grinding and effective sorting of raw materials of organic and inorganic origin.

Differential grinding is a process that allows you to get homogeneous particles with a given size and shape in the required geometric range. The dispersion of fractions can be 40-150 μm (0.05-0.15 mm, adjustable). Thanks to advanced technologies, the equipment maintains productivity up to 500 kg/h (regulated according to each type of raw material), which provides:

= Stable grinding quality without overheating.

Високу якість готового продукту.

Reduction of operating costs for consignment materials.

Energy efficiency and optimization of production processes.

Productivity and Specifications

The line productivity is not fixed, since the equipment is multi -purpose and is adjusted to different technological requirements. Optimal productivity is determined by the type of raw material and the degree of crushing. The main criterion of maximum load is the permissible value of the drive current.

Recommended productivity for one line: 300-500 kg/h with a source fraction 50-150 μm. Due to the modular design, it is possible to increase productivity by adding the dispersion units.

Flexibility of grinding

The use of the roller coaster of changing kinematics allows you to accurately adjust the degree of grinding in accordance with technological requirements.

The process includes:

Raw material supply-through the hopper and sloping augers the material is fed to the roll.

= Main grinding - on the roll machine of changed kinematics without overheating.

Sorting- in centrifugal two- or three-factional sneaker (Switzerland production) for calibration of particles.

= Finishing - sorted particles are unloaded into bags or transported further. Large particles return to re -grind.

To increase the efficiency of work, the speed of the rotor of the oster is regulated from the control panel.

(// tractor-service.com)

= Equipment equipment

Feed dispenser - 1 pc., 1 kW.

= Auger sloping - 4 pcs., 4,5 kW (1.5 + 3 kW). ROOK MACHINE OF CHANGED KINEMATICS "VVZK" - 2 pcs., 17 kW (8.5 × 2). The centenary two- or three-factional sich is 1 pc, 2.2 kW

Валковий верстат змінюваної кінематики «ВВЗК» – 2 шт., 17 кВт (8,5 × 2).

Просіювач відцентровий дво- або трифракційний – 1 шт., 2,2 кВт.

Control cabinet - 1 pc.

Electricals - 1 set.

Total set power: 29.1 kW

Продуктивність: до 500 кг/год.

Фракція на виході: 50-150 мкм (регульована).

Застосування Дисперсифікатора

The "Dispersion" is ideal for food, agrarian, pharmaceutical and chemical industry, allowing to obtain fine powder powder materials with given parameters.

= Equipment is suitable for grinding:

Cereals, legumes and oilseeds: amaranth, Jerusalem artichoke=, buckwheat, sorghum, mustard, flax, technical hemp, cocoa beads, coffee beans. Food powders and spices: sugar, salt, dried vegetables, turmeric, cinnamon, ginger.

Харчових порошків та спецій: цукор, сіль, сушені овочі, куркума, кориця, імбир.

= Protein additives: meal, protein concentrates, feed proteins.

Mineral powders: limestone, gypsum, dolomit, soda, ascorbic acid.

= Fibrous materials: miscanthus, sawdust, wood flour, cellulose.

= Conclusion

The Dispersion is the best solution for high -precision grinding, grinding and sorting materials. High productivity, economy, stability and flexibility of settings make it the ideal choice for enterprises seeking to get a quality product with minimal cost.

= Bioecope GC offers innovative industrial equipment for high -precision grinding and grinding raw materials into flour and powders. Our unique solution "Dispersion" is a complex of equipment that provides differential grinding and effective sorting of raw materials of organic and inorganic origin.

Differential grinding is a process that allows you to get homogeneous particles with a given size and shape in the required geometric range. The dispersion of fractions can be 40-150 μm (0.05-0.15 mm, adjustable). Thanks to advanced technologies, the equipment maintains productivity up to 500 kg/h (regulated according to each type of raw material), which provides:

= Stable grinding quality without overheating.

Високу якість готового продукту.

Reduction of operating costs for consignment materials.

Energy efficiency and optimization of production processes.

Productivity and Specifications

The line productivity is not fixed, since the equipment is multi -purpose and is adjusted to different technological requirements. Optimal productivity is determined by the type of raw material and the degree of crushing. The main criterion of maximum load is the permissible value of the drive current.

Recommended productivity for one line: 300-500 kg/h with a source fraction 50-150 μm. Due to the modular design, it is possible to increase productivity by adding the dispersion units.

Flexibility of grinding

The use of the roller coaster of changing kinematics allows you to accurately adjust the degree of grinding in accordance with technological requirements.

The process includes:

Raw material supply-through the hopper and sloping augers the material is fed to the roll.

= Main grinding - on the roll machine of changed kinematics without overheating.

Sorting- in centrifugal two- or three-factional sneaker (Switzerland production) for calibration of particles.

= Finishing - sorted particles are unloaded into bags or transported further. Large particles return to re -grind.

To increase the efficiency of work, the speed of the rotor of the oster is regulated from the control panel.

(// tractor-service.com)

= Equipment equipment

Feed dispenser - 1 pc., 1 kW.

= Auger sloping - 4 pcs., 4,5 kW (1.5 + 3 kW). ROOK MACHINE OF CHANGED KINEMATICS "VVZK" - 2 pcs., 17 kW (8.5 × 2). The centenary two- or three-factional sich is 1 pc, 2.2 kW

Валковий верстат змінюваної кінематики «ВВЗК» – 2 шт., 17 кВт (8,5 × 2).

Просіювач відцентровий дво- або трифракційний – 1 шт., 2,2 кВт.

Control cabinet - 1 pc.

Electricals - 1 set.

Total set power: 29.1 kW

Продуктивність: до 500 кг/год.

Фракція на виході: 50-150 мкм (регульована).

Застосування Дисперсифікатора

The "Dispersion" is ideal for food, agrarian, pharmaceutical and chemical industry, allowing to obtain fine powder powder materials with given parameters.

= Equipment is suitable for grinding:

Cereals, legumes and oilseeds: amaranth, Jerusalem artichoke=, buckwheat, sorghum, mustard, flax, technical hemp, cocoa beads, coffee beans. Food powders and spices: sugar, salt, dried vegetables, turmeric, cinnamon, ginger.

Харчових порошків та спецій: цукор, сіль, сушені овочі, куркума, кориця, імбир.

= Protein additives: meal, protein concentrates, feed proteins.

Mineral powders: limestone, gypsum, dolomit, soda, ascorbic acid.

= Fibrous materials: miscanthus, sawdust, wood flour, cellulose.

= Conclusion

The Dispersion is the best solution for high -precision grinding, grinding and sorting materials. High productivity, economy, stability and flexibility of settings make it the ideal choice for enterprises seeking to get a quality product with minimal cost.

|

= € Nikolaevich

Магазин, контакти Region: | |

Евгений Николаевич/ Reviews, Info.=/= Estimation Activity | |

|

Phone:

=+38 (XXXXXXX

Display

| |

| Skype: Mardukk1 | |

| http://www.bioekoprom.com.ua | |

= ID ad: #1330632

= (added by the registered user, registration date: 19-12-2015)

Додано / Оновлено: 22-06-2025 10:25

(Topical, to: 22-06-2026)

Постійна адреса оголошення:

Shows / views for today:?, Total:? || certain 318

= similar ads

= among them there are many interesting ...

Всього 38 similar ads= in the heading "Flour and large equipment"

all Ukraine: agricultural machinery, equipment, equipment, equipment, equipment, equipment, equipment, equipment, equipment, equipment, equipment, equipment. Inventory = 49894===/ = food industry (Equipment) land 1466 / = flour -milling and large equipment 38

Чернівецька обл.: agricultural machinery, equipment, inventory===221== ||umber 473 /=Харчова промисловість (обладнання) 8 /== flour -milling and large -scale equipment Bestolnyh was announced without registration ... 5