Glass for greenhouses

Glass is the oldest of all types covering materials. The firstgreenhouses made of glass appeared in the 16th century in France. They were called greenhouses, where all kinds of plants were grown - from flowers to exotic heat-loving trees imported from equatorial forests. Constructions were gradually improved, as were the issues of agricultural technology, but already from the first steps of application, the shortcomings of this material were noticeable.

Labour-intensive installation

Each sheet of glass must be cut to a certain size and inserted between the elements of the frame . If you cut off more than necessary, a gap will form in the structure. If less, the glass will be too large. You can re-cut at least 5 mm from the edge, as well as cut dirty, wet or cold glass - it breaks off not along the cutting line. A special tool is used for cutting - a glass cutter, the cutting element of which is a 0.16-carat diamond (1 carat is 0.2 g). Roller glass cutters are worse, they last only a few times. All this takes time, especially compared to film. It is problematic to glaze a greenhouse in the wind, even a weak one. It is also difficult to replace cracked glass.

Fragility

As a result of distortions of the frame, for example, in places of soil fluctuations (earthquakes) or under an insufficiently rammed base for the foundation, under its own weight and snow, any - any draft will result in cracks on the glass and the destruction of the greenhouse. Whereas forgreenhouse film thanks to its elasticity, everything will pass.

Heaviness of the metal frame and high cost

Unlike a light film, glass significantly increases the load on the frame, rafters and foundation. Therefore, all glass greenhouses are very complex structures, which are practically impossible to build independently in the conditions of home plots: complex calculations of wind and snow loads are required, starting with the distance between the columns, and ending with the margin of safety in the event of a heavy snowfall, which is possible once in 30-40 years Because of this, the cost of a glass greenhouse is currently about 1-1.5 million euros. But in the case of film ones, the price is much lower, and some "liberties" are possible during construction, and they are much simpler.

The need for sealants

Previously in structures with steel bars (elements glass fastening) the glass was fixed with the help of special clamps (clamps). Mastic was added to them, which retains elastic properties in the temperature range from -40 to +80°C. It was applied in 2 doses. First, the first layer was applied to the surface of the studs, and after the glass was inserted and fixed with staples, the outside was coated. Up to 10 tons of mastic, which is not cheap, was used for 1 hectare. But over time, due to temperature fluctuations in winter and summer, this mastic crumbled. And in a few years I had to repeat such smearing, which means I had to buy mastic. Delay in this or poor performance led to a sharp increase in heating losses, which often significantly exceeded the calculated ones. Because of this, glass greenhouses were additionally covered with polyethylene film around the perimeter from the outside or from the inside. Only in modern designs of Dutch or "Venlo-type" greenhouses was it possible to replace mastics with rubber gaskets and new types of sealants, which made it possible to significantly reduce heating costs. In them, the glass does not need to be cut - it is produced in a clearly standardized size.

To this day, many manufacturers are guided by the outdated standard GOST 111-90 for sheet glass. However, the modern market is focused on the production of high-quality glass for double-glazed windows in accordance with the European standard EN 572-2.

Since the "Venlo-type" greenhouses have taken the leading place in the world market, Dutch companies that provide services for their construction , provide imported glass. Silver and tin oxides are added to the molten mass (using the float method). They give it a beautiful shine without blackness (when viewed against the light). It determines its higher reflectivity, less fragility.

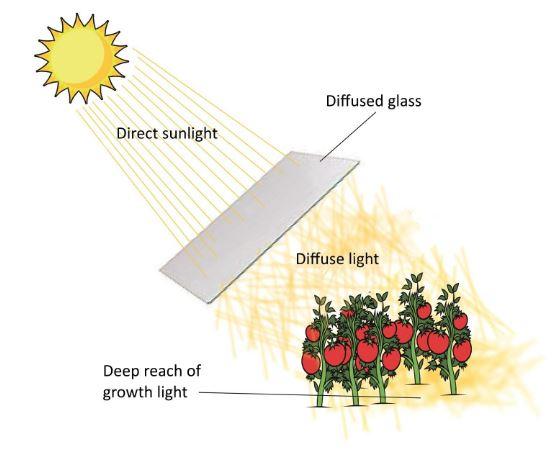

Diffuse glass - the cost is worth the effect

In recent years, it was possible to research and change the internal structure of glass, creating the so-called light scattering (or diffuse ). This is one of the most outstanding innovations of recent years in the field of closed soil. A special chemical solution is poured onto the surface of ordinary glass in an even layer, which reacts with glass molecules (silicon, sodium, calcium oxides), dissolving them. Dissolved compounds form silicon and sodium fluorides on the surface in the form of conical crystals connected to glass molecules with sizes ranging from hundredths to tenths of a mm. With the help of nanotechnology, it was possible to orient these crystals when an electric current passes in one direction. It turned out to be something like frosted glass, which disperses the current of light, but the light transparency did not decrease. Such glass not only makes the microclimate more comfortable for plants and the work of service personnel in intense heat, but also reduces the formation of condensation (and therefore plant diseases), while providing even higher light transmission than in the case of ordinary glass.

The effect of diffused glass

All this together gives an increase in yield by 10-12%. Greenhouses with such glass have already been built in Australia, the Netherlands, Belgium, Denmark, the USA, Switzerland, England, and France. The cost of diffused glass is 10-15 euros/m.2.

In conclusion, we can say that the popularity of this oldest covering material continues to grow.