Greenhouse film

Ordinary polyethylene film (PE), which produced since the 60s, not very suitable forgreenhouses. Among all its shortcomings, there are three main ones.

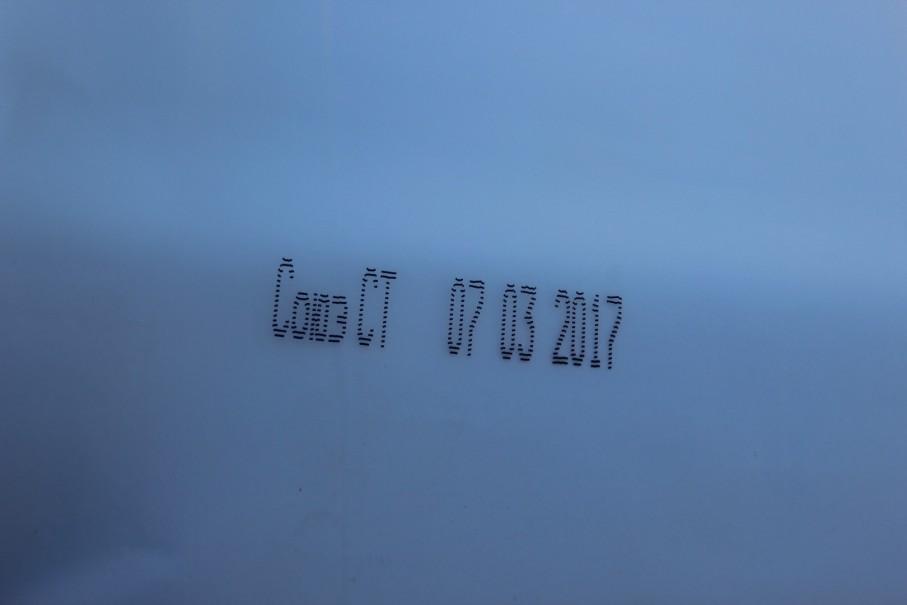

The first drawback is short-lived: under the influence of the destructive action of solar ultraviolet, the film loses its primary properties: after 3-4 months it loses elasticity, strength, begins to crack... This process is called "aging". To combat it, ultraviolet (abbreviated - UV) light stabilizers are used. Thisfilm was called light-stabilized. For convenience, such films, for multi-season use, are tinted. For example, 2-season has a yellow shade, 5-season - red, 4-season - green, 6-season - blue. When covering, you need to direct the side with the UV light stabilizer to the outer side. In order to make it easier to find, some manufacturers put the manufacturer's logo, production date, etc. on this side using flexo printing. It is also an effective protection against counterfeiting: if, for example, the film has the inscription "Soyuzpolimer", it is difficult to pass it off as a film of Hungarian or Spanish production.

Inscription on the film with the date of production and the manufacturer's logo - protection against counterfeiting and a hint on which side to mount the film on the frame from the outside

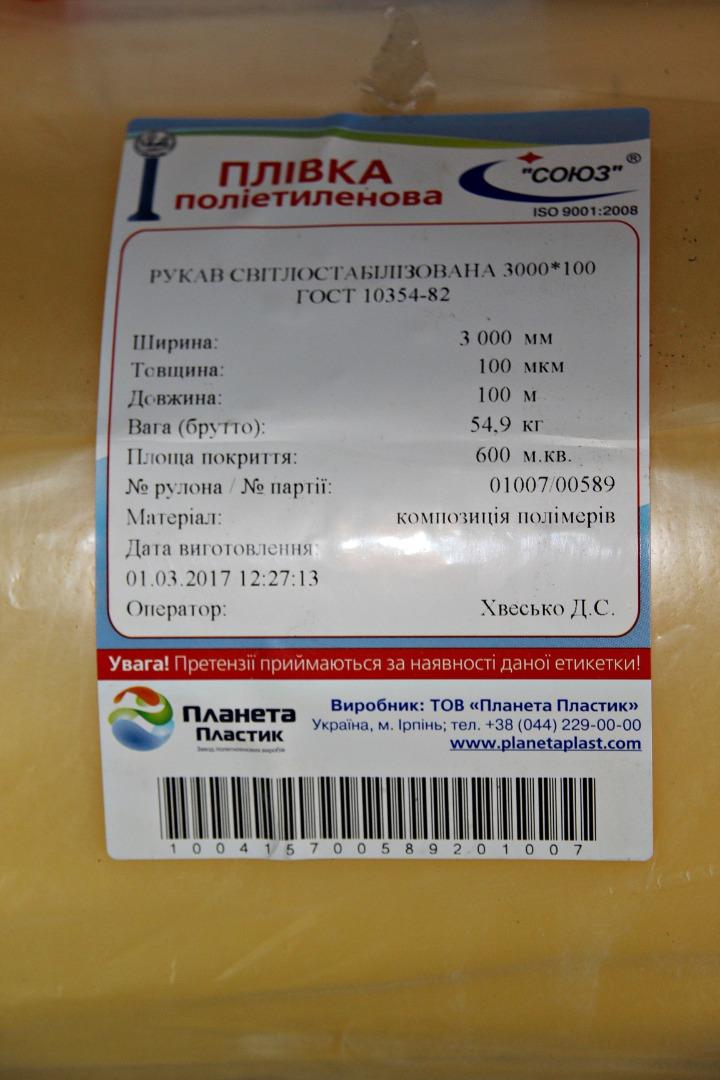

On the label of each roll, the batch number, manufacturer's barcode, length and width in reverse

The second disadvantage of the film is large heat losses. Unfortunately, of all types of covering materials, compared to glass,agrofiber andpolycarbonate it is the coolest under it, because its only a few microns thick. To solve this problem, a so-called heat-retaining film (with infrared absorbers) was created. They are marked with IR, hence the name of the film - IR film. Under such a film, the temperature is 3-5оC higher than under others. A number of absorbers are a trade secret.

The third disadvantage of a conventional film is the formation of condensate on the inner side due to the electrostatic charge on the surface. Especially a lot of drops are formed in strong heat, late openingventilation. Such drops are shaken by gusts of wind, fall on service personnel and plants, which leads to the spread of fungal diseases and the lens effect. Engineers managed to solve this problem by creating a film with an "anti-fog effect" (fog). It has no electrostatic charge, as a result of which water drops do not condense on the inside, but flow down the surface of the film to the floor.

Condensate - on an ordinary film from the inside - one of the disadvantages of an ordinary film. Today, films with an "anti-fog effect" have become fashionable.

There is also a light-scattering film - the composition of which includes particles of kaolin. It scatters direct sunlight due to a cloudy milky shade at the cost of some reduction in transparency. In strong heat, overheating of plants under it is less than under others.

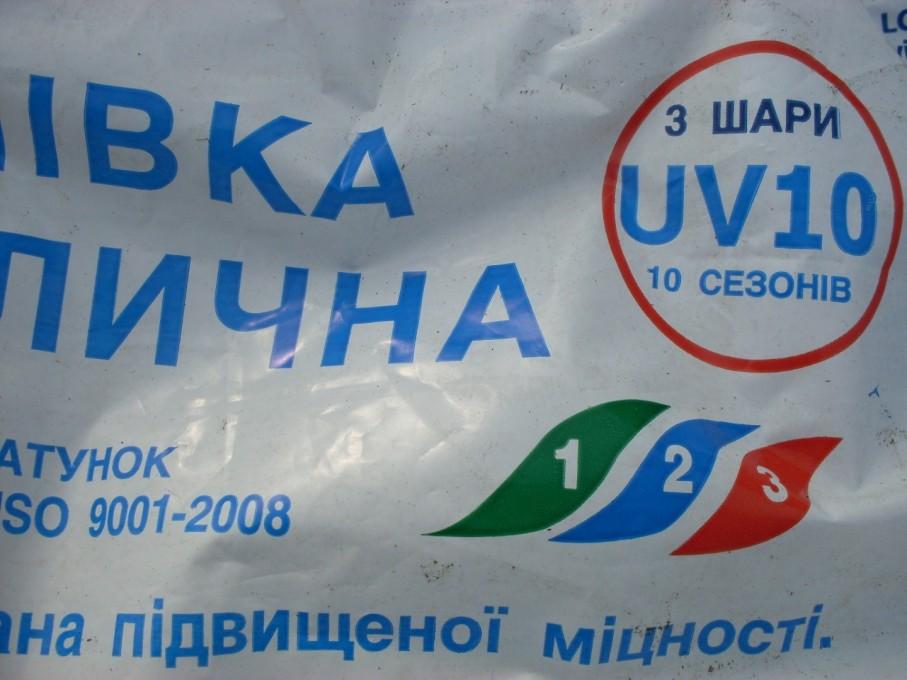

Is it possible to create a film that would combine all these properties in itself - it would be both heat-retaining and stabilized, and with an anti-fog effect, and light scattering? Unfortunately, no - some of these properties are controversial. For example, by increasing light scattering (the film becomes cloudy and milky, and this impairs transparency). However, modern technologies were able to achieve this by creating a so-called multilayer film using co-extrusion. Coextrusion is the process of extruding two or more liquid polymers into a multilayer structure or depositing two or more liquid polymers on a substrate for further formation. The upper layer of such a film contains protection against the destructive effects of solar UV rays - UV stabilizers. Medium - low pressure polyethylene - strong rigid material. The lower one is antiphon additives. Therefore, they were able to achieve previously unseen properties in one film. Such a film is currently the most popular and fashionable in the world.

A separate type of film is a reinforced film - it consists of 2 layers of film, between which a frame made of polypropylene twine or other non-metallic materials is embedded. Such a film is the most expensive, recommended for regions with strong winds, is strong and durable. It is produced only by individual manufacturers.

Its main drawback is its high price. In terms of strength, the multilayer film is in second place after it, which is why it has gained the highest popularity.

The most fashionable multilayer film today

All films can be produced with a width of 3 m, 6 m , 12 and 16 m, while the length of the roll is indicated on the label and in the manufacturer's price list. The greater the width in the turn, the fewer welding places there will be, but the film will be more expensive.