/ Agricultural equipment, equipment, inventory / Spare parts for agricultural machinery / Spare parts for machinery post-harvest processing / Spare parts for conveyors / SCL20 channel cutter for plug connectors...

Sell / buy

Gutter cutter SKL20 For connectors K27 K28, Kharkiv region.

Price3100 UAH.

Region:all of Ukraine,

Kharkov region.

Updated:

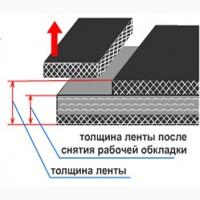

Intended for removing part of the rubber lining conveyor belt when docked with detachable connectors K-27 K-28

When removing the cover with the SKL20 groove cutter, the wear of the K-27 K-28 staple is significantly reduced and the service life of the butt joint K-27 K-28 is increased.

Mechanical connection of conveyor belt K-27 K-28

Mechanical joining of conveyor belts with detachable connectors of the K20 system type K-27 K-28

Mechanical joining of conveyor belts with connectors K-27 and K-28 is the fastest method of joining conveyor belts. The only significant drawback of this joining method is the service life of connectors, which is lower than in hot and cold vulcanization.

The main purpose of mechanical connectors of conveyor belts K-27 K-28

Docking of conveyor belts on mobile conveyors

Quick docking of tapes in the event of an emergency situation on the conveyor.

Docking of tapes in case of impossibility of using cold or hot vulcanization.

The main advantages of mechanical joining of conveyor belts with connectors K-27 K-28

Minimum joining time (example: the time spent on the K-27 or K-28 butt joint of a conveyor belt with a width of 800 - 1200 mm - 20-30 minutes);

Execution of joints in any climatic and production conditions (at negative ambient temperatures, high dustiness, etc.);

(//tractor-service.com)

K20 technology does not require complex technological training of service personnel;

Independence from sources of electricity.

Additional advantages of mechanical docking of conveyor belts with connectors K-27 K-28

It allows connecting conveyor belts with a thickness from 7 to 20 mm (with the removal of the upper cover), strength up to 1000 N/mm);

It allows to reduce the consumption of the conveyor belt per joint (up to two meters of tape is saved, which means that the costs of its purchase are reduced);

work is performed by 2-3 people (and often, one person is enough);

The possibility of performing butt joints K-27 K-28 directly on the conveyor, in the warehouse, in the workshop, adjacent shops;

Docking tapes of any width; The possibility of using a spare belt web on short lengths of conveyors (replacement efficiency);

There is no complicated cutting of the ends of the tapes, simple cutting at an angle of 90 is used;

High transverse and longitudinal flexibility of the butt joint, which does not create tension during the passage of the drums and does not prevent the tape from forming a groove;

A small specific weight of the joint, which allows it to be used when there are tapesweights;

The thickness of the joint is equal to the thickness of the tape (after pressing the K-27 K-28 staples), which does not make it difficult to pass through the cleaning devices;

Reasonable use on conveyors of the mining industry (shortening and lengthening of the conveyor);

Effective application in the event of an emergency situation on the conveyor (replacement or completion of a joint) - technological downtime is reduced to a minimum.

Restrictions on the use of mechanical joining of tapes with staples K-27 K-28

Only for conveyor belts with a fabric frame

When removing the cover with the SKL20 groove cutter, the wear of the K-27 K-28 staple is significantly reduced and the service life of the butt joint K-27 K-28 is increased.

Mechanical connection of conveyor belt K-27 K-28

Mechanical joining of conveyor belts with detachable connectors of the K20 system type K-27 K-28

Mechanical joining of conveyor belts with connectors K-27 and K-28 is the fastest method of joining conveyor belts. The only significant drawback of this joining method is the service life of connectors, which is lower than in hot and cold vulcanization.

The main purpose of mechanical connectors of conveyor belts K-27 K-28

Docking of conveyor belts on mobile conveyors

Quick docking of tapes in the event of an emergency situation on the conveyor.

Docking of tapes in case of impossibility of using cold or hot vulcanization.

The main advantages of mechanical joining of conveyor belts with connectors K-27 K-28

Minimum joining time (example: the time spent on the K-27 or K-28 butt joint of a conveyor belt with a width of 800 - 1200 mm - 20-30 minutes);

Execution of joints in any climatic and production conditions (at negative ambient temperatures, high dustiness, etc.);

(//tractor-service.com)

K20 technology does not require complex technological training of service personnel;

Independence from sources of electricity.

Additional advantages of mechanical docking of conveyor belts with connectors K-27 K-28

It allows connecting conveyor belts with a thickness from 7 to 20 mm (with the removal of the upper cover), strength up to 1000 N/mm);

It allows to reduce the consumption of the conveyor belt per joint (up to two meters of tape is saved, which means that the costs of its purchase are reduced);

work is performed by 2-3 people (and often, one person is enough);

The possibility of performing butt joints K-27 K-28 directly on the conveyor, in the warehouse, in the workshop, adjacent shops;

Docking tapes of any width; The possibility of using a spare belt web on short lengths of conveyors (replacement efficiency);

There is no complicated cutting of the ends of the tapes, simple cutting at an angle of 90 is used;

High transverse and longitudinal flexibility of the butt joint, which does not create tension during the passage of the drums and does not prevent the tape from forming a groove;

A small specific weight of the joint, which allows it to be used when there are tapesweights;

The thickness of the joint is equal to the thickness of the tape (after pressing the K-27 K-28 staples), which does not make it difficult to pass through the cleaning devices;

Reasonable use on conveyors of the mining industry (shortening and lengthening of the conveyor);

Effective application in the event of an emergency situation on the conveyor (replacement or completion of a joint) - technological downtime is reduced to a minimum.

Restrictions on the use of mechanical joining of tapes with staples K-27 K-28

Only for conveyor belts with a fabric frame

|

Shop, contacts | |

Leonid Chepurny/ отзывы, инфо./ activity evaluation | |

|

Phone:

+380xxxxxx

show

| |

All user ads ~24 | |

Ad ID: #1122098

(added by a registered user, registration date: 20-04-2021)

Added/Updated: 11-28-2025 17:04 (current, until: 11-28-2026)

Permanent ad address:

Showed / watched for today: ?, total: ?

Similar ads

Among them there are many interesting ones...

All Ukraine: Spare parts for agricultural machinery 18917 / Spare parts for post-harvest machinery processing 885 / Spare parts for transporters 196

Kharkiv region: Spare parts for agricultural machinery 4781 / Spare parts for machinery for post-harvest processing 30 / Spare parts for to transporters 23