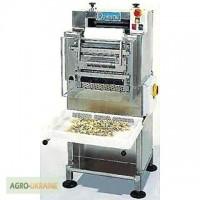

/ Agricultural machinery, equipment, inventory / Food industry (equipment) /Pasta products (equipment) / La Monferrina 300 pasta production line...

For sale / buy

bu (used)

Used La Monferrina 300 kg/hour pasta production line, Transcarpathian region.

Region:all of Ukraine,

Transcarpathian region.

(Uzhhorod)

Updated:

Composition of the line:

1. Загрузочное устройство

2. Automatic press for short-cut macarons. K300 with a capacity of 250 - 300 kg/hour.

3. Cooling system of the compression unit and press head K300 with a closed circuit.

4. Preliminary drying (Trabatto)

5. Electric drying cabinets (6 cabinets included)

Production process:

Flour, grits or similar raw materials are sifted and fed into the press by a loading device.

Raw materials are dosed and pre-mixed with the addition of water, eggs and/or a mixture of eggs and water.(//tractor-service.com)

After this preliminary operation, the dough is kneaded under vacuum and sent to the chamber for pressing short-cut pasta.

Macaroni is cut to the required size with a special knife and falls directly onto the trabatto sieve, where preliminary drying takes place; this allows you to shorten the final drying time andget macaroni of the highest quality, avoiding their breakage during the final drying. From the trabatto, dried macaroni are transported to drying cabinets, and after the drying cycle is finished, the macaroni is ready for packaging.

Macaroni can be fed into asilo-accumulator, from which they are fed into the hopper of an automatic packaging machine.

Year of issue: 2006

You are guaranteed to receive a profitable offer upon request to our email address: office@ar-tech.com.ua.

We will answer all your questions by phone: +380997174185 / +380970308051, +380953376425, or by e-mail.

Proposals are provided upon request.

The price on the site may differ from the actual price.

We look forward to hearing from you.

Sincerely, AR-Tech company.

1. Загрузочное устройство

2. Automatic press for short-cut macarons. K300 with a capacity of 250 - 300 kg/hour.

3. Cooling system of the compression unit and press head K300 with a closed circuit.

4. Preliminary drying (Trabatto)

5. Electric drying cabinets (6 cabinets included)

Production process:

Flour, grits or similar raw materials are sifted and fed into the press by a loading device.

Raw materials are dosed and pre-mixed with the addition of water, eggs and/or a mixture of eggs and water.(//tractor-service.com)

After this preliminary operation, the dough is kneaded under vacuum and sent to the chamber for pressing short-cut pasta.

Macaroni is cut to the required size with a special knife and falls directly onto the trabatto sieve, where preliminary drying takes place; this allows you to shorten the final drying time andget macaroni of the highest quality, avoiding their breakage during the final drying. From the trabatto, dried macaroni are transported to drying cabinets, and after the drying cycle is finished, the macaroni is ready for packaging.

Macaroni can be fed into asilo-accumulator, from which they are fed into the hopper of an automatic packaging machine.

Year of issue: 2006

You are guaranteed to receive a profitable offer upon request to our email address: office@ar-tech.com.ua.

We will answer all your questions by phone: +380997174185 / +380970308051, +380953376425, or by e-mail.

Proposals are provided upon request.

The price on the site may differ from the actual price.

We look forward to hearing from you.

Sincerely, AR-Tech company.

|

Author, contacts | |

Anatoly Hrab/ reviews , info. / activity evaluation | |

|

Phone:

+380xxxxxx

show

| |

| Telegram: +380953376425 | |

| Viber: +380953376425 | |

| Whatsapp:+380953376425 | |

| http://ar-tech.com.ua/ | |

| youtube.com/@ARTechUA/videos | |

All user ads ~79 | |

Ad ID: #860759

(added by a registered user, registration date: 2015-03-24)

Added / Updated: 08-30-2024 11:10 (current, until: 30-08-2025)

Permanent Ad Address:

Shows / views for today: ?, total: ?

Similar ads

There are many interesting...

Total13 similar adsin the section "Equipment for the production of pasta products"

All Ukraine: Agricultural machinery, equipment, inventory 51247 / Food industry (equipment) 1524 / Pasta (Equipment)| ||393 13

Transcarpathian region: Agricultural machinery, equipment, inventory 282 / Food industry (equipment) 65 / Pasta products (equipment) 12