/ Agricultural machinery, equipment, inventory / Food industry (equipment) / Equipment for milk processing / Various milk processing equipment + in assortment / Milk pasteurizer 300 liters

Sell / buy

Milk pasteurizer 300 liters, Rivne region.

Price210,000 UAH.

Region:all of Ukraine,

Rivnen region.

(M. Rivne, Volodymyra Stelmakh St. 18A)

Updated:

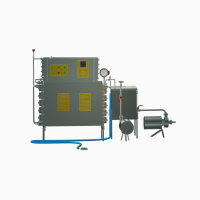

Milk pasteurizer 300 liters - designed for heat treatment of milk, cream and other food products, works in the temperature range from 15°С to 90°С. During heat treatment in the pasteurizer, pathogenic microflora is destroyed and neutralized. This increases the shelf life of dairy products without changing the useful, taste, and nutritional properties. Heating takes place without boiling, this excludes changes in organoleptic indicators, destruction of vitamins and enzymes.

The milk pasteurizer is intended for: pasteurization of milk, before cheese production, for pasteurization of milk under the separator for the production of cream andbutter, for pasteurization of milk on the farm beforedrinking calves with pasteurized fresh milk.

All materials of the milk pasteurizer: the outer casing, the inner container, the lid, the stirrer, the tap for draining the product - are made of durable AISI304 food-grade stainless steel. The milk pasteurizer will be useful both for drinking calves on dairy farms and for enterprises involved in milk processing.

The milk pasteurizer allows the following operations:

heating, pasteurization of milk, cream and other food products;

fermentation of fermented milk products;

languishing of milk;

перемішування продукту;

cooling.

The pasteurization process consists of successive stages, which are controlled manually or automatically and displayed on the control unit:

Product download.

Set the pasteurization temperature. The heating of the product depends on the power of the heating elements installed on the equipment (30 minutes in total).(//tractor-service.com)

After the product is heated, the set temperature maintenance mode is activated.

The operator turns off the heating and opens the faucet with running water (Optional: automatic mode).

The product is cooling.

During cooling, the display shows the current temperature of the product.

Cooling with running water to 15˚C (up to 2-4˚C with ice water (an ice water generator is required, the pasteurizer must be made with a panel jacket).

The pasteurization process is over.

At the request of the customer, the pasteurizer can be equipped with a unit with automatic or semi-automatic control. It is also possible to individually manufacture pasteurizers according to the customer's dimensions, optimal choice of power of heating elements.

The 300 liter milk pasteurizer allows the following pasteurization modes:

long-term or low-temperature - heating to 63-65 °C with exposure for 25-30 minutes;

short-term - heating to 72-76 ° C with holding at this temperature for 20-60 s;

instant - 85 °C and above without holding.

Also, our company additionally develops technological maps and carries out start-up, debugging and installation work with personnel training.

For more detailed information, contact our managers!

Company IKR GROUP.

The milk pasteurizer is intended for: pasteurization of milk, before cheese production, for pasteurization of milk under the separator for the production of cream andbutter, for pasteurization of milk on the farm beforedrinking calves with pasteurized fresh milk.

All materials of the milk pasteurizer: the outer casing, the inner container, the lid, the stirrer, the tap for draining the product - are made of durable AISI304 food-grade stainless steel. The milk pasteurizer will be useful both for drinking calves on dairy farms and for enterprises involved in milk processing.

The milk pasteurizer allows the following operations:

heating, pasteurization of milk, cream and other food products;

fermentation of fermented milk products;

languishing of milk;

перемішування продукту;

cooling.

The pasteurization process consists of successive stages, which are controlled manually or automatically and displayed on the control unit:

Product download.

Set the pasteurization temperature. The heating of the product depends on the power of the heating elements installed on the equipment (30 minutes in total).(//tractor-service.com)

After the product is heated, the set temperature maintenance mode is activated.

The operator turns off the heating and opens the faucet with running water (Optional: automatic mode).

The product is cooling.

During cooling, the display shows the current temperature of the product.

Cooling with running water to 15˚C (up to 2-4˚C with ice water (an ice water generator is required, the pasteurizer must be made with a panel jacket).

The pasteurization process is over.

At the request of the customer, the pasteurizer can be equipped with a unit with automatic or semi-automatic control. It is also possible to individually manufacture pasteurizers according to the customer's dimensions, optimal choice of power of heating elements.

The 300 liter milk pasteurizer allows the following pasteurization modes:

long-term or low-temperature - heating to 63-65 °C with exposure for 25-30 minutes;

short-term - heating to 72-76 ° C with holding at this temperature for 20-60 s;

instant - 85 °C and above without holding.

Also, our company additionally develops technological maps and carries out start-up, debugging and installation work with personnel training.

For more detailed information, contact our managers!

Company IKR GROUP.

|

Store, contacts | |

Vadym / feedback, info. / activity assessment | |

|

Phone:

+380xxxxxx

show

| |

All user ads ~194 | |

Ad ID: #1297819

(added by a registered user, registration date: 07-25-2018)

Added / Updated: 10-27-2025 08:05 (current, until: 10-27-2026)

Permanent Ad Address:

Impressions / views for today: ?, total: ?

Similar ads

Among them there are many interesting ones...

Total183 similar adsin the heading "Milk processing equipment"

All Ukraine: Food industry (equipment) 1406 / Milk processing equipment 183 / Various milk processing equipment + in assortment 75

Rivna region: Food industry (equipment) 83 / Equipment for processing of milk 48 / Various milk processing equipment + in assortment 28