/ Agricultural machinery, equipment, inventory / Animal husbandry, poultry farming (equipment) / Slaughter and primary processing / Slaughter + primary processing lines / Rabbit slaughter line performance: up to 1000...

Продам / купити

Линия убоя кроликов производительность: до 1000 голов в смену (120 голов в час), Львівська обл.

Price10 UAH.

Region:all of Ukraine, | ||143

Львівська обл.

(Lviv)

Updated:

• Slaughter area (dirty workshop) - where rabbits are slaughtered with a cut in the throat and bleeding;

• Processing area (clean shop) with a refrigerator for storing products.

Productivity: 1000 heads per shift (120 heads per hour)

Functionality: Anatomical sawing

Vacuum packing (possible HMS)

Packing in stretch tape on a mat.

Cleaning and freezing of offal

A complex for the slaughter and processing of rabbits, which includes a meat processing zonemeat processing, and a zone for primary cleaning of intestines.

Preparation of rabbits for slaughter

Slaughter of rabbits is carried out when the animal reaches the age of 4-4.5 months. The degree of demand is also an important indicator. If the animal does not reach certain indicators, it is sent to intensive feeding.

But the most important criterion for determining the time of slaughter is the molting period, since it is possible to obtain a high-quality skin only after the molting stage is completed.

The duration of the first moult is 2-2.5 months, it begins after the animal reaches 1 month and continues until the age of 3-3.5 months. Then there is a break, and after about 2 weeks, the second molting period begins, which lasts until the age of 5-5.5 months.

When molting ends, you can start slaughtering. 12 hours before slaughter, the rabbit should not be fed so that the intestines of the animal are completely cleansed. You can only give water, then the rabbit will not have extraneous unpleasant smells.

Methods and ways of slaughtering rabbits

There are many ways to slaughter rabbits for meat, but the following are the most common:

Bloodless method of slaughtering rabbits.

The most frequently used method. It is carried out as follows: the rabbit is taken out ofcells, take the hind legs, when the animal stops twitching, hit the occipital region (behind the ears) with a wooden stick. It is better to choose a stick with a square section so as not to damage the skin. A tool with a round cross-section is recommended to be additionally wrapped with a cloth or a rubber pad should be attached to it. Blood flows from the nose and ears after the blow.

French method

The rabbit is taken by the ears and hind legs, raised with its paws upwards, when the animal calms down, jerked sharply, the spinal cord ruptures, and instant death ensues. Obsekrovlivanie is carried out also through the nose and ears.

Cutting the throat

For stronger exsanguination, the animal's throat is cut, the heart muscle continues to contract and expel blood for a few more minutes, thus, the meat is lighter, but the skin loses its marketable appearance due to the cut, and the fur is stained with blood, which is why it suffers significantly ego quality.

Slaughter by electric current

This method is mainly used in large slaughterhouses. The animal's head is put into a special installation where voltage is applied. After an electric shock, the heartbeat is preserved, which ensures good bleeding of the carcass and high quality meat.

Of all the presented methods, the most humane are the bloodless ones. It is believed that cutting the throat causes much greater suffering to the animal than the rest.

The suggested solution includes:

• Reception vestibule for rabbits

• Rabbit slaughter line, with a capacity of up to 120 heads/hour.

• Room for processing mucous membranes and salting skins

• Room for anatomical sawing and packaging.

• Refrigerators

• Veterinarian's office

• Changing room for 6 people

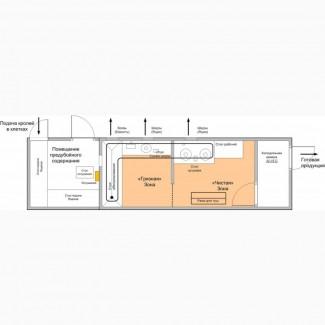

The slaughter and processing complex is designed based on the requirement to minimize the occupied land space. However, all the requirements for the organization of workplaces at meat industry enterprises and compliance with the correctness of technological processes were taken into account.

In order to minimize the occupied land space, production premises are united by zones and arranged in volume.

Production premises are located in such a way that all dirty production - slaughter and accompanying processes and technological premises are located symmetrically, all premises for meat processing and production of semi-finished products, including refrigerating chambers for long-term storage, are located on the other side.

The complex is a finished solution and has no possibility to increase productivity.

Technological characteristics of the rabbit slaughter complex(//tractor-service.com)

P/n Characteristics Значение

1 Рабочие места 9

1.1 Fighter of the mud guild (max.) 2

1.2 Fighter of pure guild (max.) 2

1.3 Worker cutting packaging 2

1.4 Working (byproducts) 1

1.5 Vetvrach 1

1.6 Handyman (supply of cells) 1

2 Water consumption rate

2.1 Slaughter, no more, l/carcass 1

2.2 Auxiliary per shift, no more, m3 2

Composition and description:

Slaughter compartment with a receiving table for stunning, a blood collection cup and 6 hangers to ensure the fixation of the rabbit carcass and blood flow into a special stainless steel tank located inside the table under the blood collection cup.

Device for electro-stunning rabbits. The device is made in a convenient compact version with an ergonomic handle and protection against direct current impact on a person. The device provides stunning of the rabbit for up to 2 minutes, ensuring the heart works and good bleeding of the carcass.

Table for skinning and gutting, equipped with a sink for rinsing hands and asterilizer. The table is made of stainless steel.

A waste disposal point made of stainless steel, equipped with a door for storing killing tools (knives, ...) and a supporting structure.

Size: 800 x 1300 x 850 mm.

Stainless steel sterilizers for processing knives. Adapted for work with knives, the handles of which are made of food-grade polyethylene. A temperature control knob and a thermostat are provided for temperature regulation.

Equipment for washing the cut carcass and the working area. The composition includes a shower unit installed on the table, a nozzle for rinsing the carcass and a flexible hose with a pistol-type nozzle for cleaning the surfaces of the working area.

Stainless steel cutting (packaging) table.

High-temperature refrigerating chamber 0...+4°C

The electrical panel is mounted in a special box made of ABC plastic with a transparent door. Electrical components of European production. All wiring is laid in sealed polypropylene pipes. There are safety sensors and protection schemes.

Water supply to the equipment is carried out through hermetic polypropylene pipes with a section of 3/4 inch. The pipelines are connected from the outside to two hot and cold water valves. Depending on the requirements, valves can have different connecting diameters. In the absence of hot water, it is possible to install a water heater.

Suspension track for manual transportation of carcasses suspended on chain hooks during various stages of processing. Anodized aluminum chains, monorail with 20 stainless steel hooks, hard stainless steel wire hanger. The monorail is made according to a closed scheme, therefore the movement of hooks with hangers takes place in a circular scheme without the need to remove and rearrange them.

The suspension path for transporting rabbit carcasses suspended on chain hooks during various stages of processing is made according to a closed circuit, so the movement of hooks with hangers takes place in a circular trajectory without the need to remove them.

Technical characteristics of the rabbit slaughter line

Characteristics Значение

Electrical connection (dry contact) 220V, 50 Hz, L, N, PE

Summer power consumption, kW/hour 10

Winter power consumption, kW/hour 12

Water quality SanPiN 2.1.4.1074-01

Water supply (cold and hot),

valve connection sizes, inch 3/4, 1

The single point of entering cold water

Давление воды From 0.03 MPa (0.3 kgf/sq. cm)

up to 0.6 MPa (6 kgf/sq. cm)

Drain (sewage), connection size, mm 110

• Processing area (clean shop) with a refrigerator for storing products.

Productivity: 1000 heads per shift (120 heads per hour)

Functionality: Anatomical sawing

Vacuum packing (possible HMS)

Packing in stretch tape on a mat.

Cleaning and freezing of offal

A complex for the slaughter and processing of rabbits, which includes a meat processing zonemeat processing, and a zone for primary cleaning of intestines.

Preparation of rabbits for slaughter

Slaughter of rabbits is carried out when the animal reaches the age of 4-4.5 months. The degree of demand is also an important indicator. If the animal does not reach certain indicators, it is sent to intensive feeding.

But the most important criterion for determining the time of slaughter is the molting period, since it is possible to obtain a high-quality skin only after the molting stage is completed.

The duration of the first moult is 2-2.5 months, it begins after the animal reaches 1 month and continues until the age of 3-3.5 months. Then there is a break, and after about 2 weeks, the second molting period begins, which lasts until the age of 5-5.5 months.

When molting ends, you can start slaughtering. 12 hours before slaughter, the rabbit should not be fed so that the intestines of the animal are completely cleansed. You can only give water, then the rabbit will not have extraneous unpleasant smells.

Methods and ways of slaughtering rabbits

There are many ways to slaughter rabbits for meat, but the following are the most common:

Bloodless method of slaughtering rabbits.

The most frequently used method. It is carried out as follows: the rabbit is taken out ofcells, take the hind legs, when the animal stops twitching, hit the occipital region (behind the ears) with a wooden stick. It is better to choose a stick with a square section so as not to damage the skin. A tool with a round cross-section is recommended to be additionally wrapped with a cloth or a rubber pad should be attached to it. Blood flows from the nose and ears after the blow.

French method

The rabbit is taken by the ears and hind legs, raised with its paws upwards, when the animal calms down, jerked sharply, the spinal cord ruptures, and instant death ensues. Obsekrovlivanie is carried out also through the nose and ears.

Cutting the throat

For stronger exsanguination, the animal's throat is cut, the heart muscle continues to contract and expel blood for a few more minutes, thus, the meat is lighter, but the skin loses its marketable appearance due to the cut, and the fur is stained with blood, which is why it suffers significantly ego quality.

Slaughter by electric current

This method is mainly used in large slaughterhouses. The animal's head is put into a special installation where voltage is applied. After an electric shock, the heartbeat is preserved, which ensures good bleeding of the carcass and high quality meat.

Of all the presented methods, the most humane are the bloodless ones. It is believed that cutting the throat causes much greater suffering to the animal than the rest.

The suggested solution includes:

• Reception vestibule for rabbits

• Rabbit slaughter line, with a capacity of up to 120 heads/hour.

• Room for processing mucous membranes and salting skins

• Room for anatomical sawing and packaging.

• Refrigerators

• Veterinarian's office

• Changing room for 6 people

The slaughter and processing complex is designed based on the requirement to minimize the occupied land space. However, all the requirements for the organization of workplaces at meat industry enterprises and compliance with the correctness of technological processes were taken into account.

In order to minimize the occupied land space, production premises are united by zones and arranged in volume.

Production premises are located in such a way that all dirty production - slaughter and accompanying processes and technological premises are located symmetrically, all premises for meat processing and production of semi-finished products, including refrigerating chambers for long-term storage, are located on the other side.

The complex is a finished solution and has no possibility to increase productivity.

Technological characteristics of the rabbit slaughter complex(//tractor-service.com)

P/n Characteristics Значение

1 Рабочие места 9

1.1 Fighter of the mud guild (max.) 2

1.2 Fighter of pure guild (max.) 2

1.3 Worker cutting packaging 2

1.4 Working (byproducts) 1

1.5 Vetvrach 1

1.6 Handyman (supply of cells) 1

2 Water consumption rate

2.1 Slaughter, no more, l/carcass 1

2.2 Auxiliary per shift, no more, m3 2

Composition and description:

Slaughter compartment with a receiving table for stunning, a blood collection cup and 6 hangers to ensure the fixation of the rabbit carcass and blood flow into a special stainless steel tank located inside the table under the blood collection cup.

Device for electro-stunning rabbits. The device is made in a convenient compact version with an ergonomic handle and protection against direct current impact on a person. The device provides stunning of the rabbit for up to 2 minutes, ensuring the heart works and good bleeding of the carcass.

Table for skinning and gutting, equipped with a sink for rinsing hands and asterilizer. The table is made of stainless steel.

A waste disposal point made of stainless steel, equipped with a door for storing killing tools (knives, ...) and a supporting structure.

Size: 800 x 1300 x 850 mm.

Stainless steel sterilizers for processing knives. Adapted for work with knives, the handles of which are made of food-grade polyethylene. A temperature control knob and a thermostat are provided for temperature regulation.

Equipment for washing the cut carcass and the working area. The composition includes a shower unit installed on the table, a nozzle for rinsing the carcass and a flexible hose with a pistol-type nozzle for cleaning the surfaces of the working area.

Stainless steel cutting (packaging) table.

High-temperature refrigerating chamber 0...+4°C

The electrical panel is mounted in a special box made of ABC plastic with a transparent door. Electrical components of European production. All wiring is laid in sealed polypropylene pipes. There are safety sensors and protection schemes.

Water supply to the equipment is carried out through hermetic polypropylene pipes with a section of 3/4 inch. The pipelines are connected from the outside to two hot and cold water valves. Depending on the requirements, valves can have different connecting diameters. In the absence of hot water, it is possible to install a water heater.

Suspension track for manual transportation of carcasses suspended on chain hooks during various stages of processing. Anodized aluminum chains, monorail with 20 stainless steel hooks, hard stainless steel wire hanger. The monorail is made according to a closed scheme, therefore the movement of hooks with hangers takes place in a circular scheme without the need to remove and rearrange them.

The suspension path for transporting rabbit carcasses suspended on chain hooks during various stages of processing is made according to a closed circuit, so the movement of hooks with hangers takes place in a circular trajectory without the need to remove them.

Technical characteristics of the rabbit slaughter line

Characteristics Значение

Electrical connection (dry contact) 220V, 50 Hz, L, N, PE

Summer power consumption, kW/hour 10

Winter power consumption, kW/hour 12

Water quality SanPiN 2.1.4.1074-01

Water supply (cold and hot),

valve connection sizes, inch 3/4, 1

The single point of entering cold water

Давление воды From 0.03 MPa (0.3 kgf/sq. cm)

up to 0.6 MPa (6 kgf/sq. cm)

Drain (sewage), connection size, mm 110

|

Author, contacts | |

Velmark M/ відгуки, інфо. / activity evaluation | |

|

Phone:

+38(xxxxxx

show

| |

| Skype: vlad013 | |

| http://www.wellmarkm.net | |

| facebook.com/wellmarkm | |

All user ads ~87| ||311 | |

Ad ID: #1000385

(added by registered user, registration date: 2013-07-21)

Added/Updated : 09-17-2024 15:05 (current, until: 09-17-2025)

Permanent Ad Address:

Shows / views for today: ?, total: ?

Similar ads

There are many interesting...

Total13 similar adsin the heading "Lines slaughter + primary processing"

All Ukraine:Livestock, poultry farming (equipment) 558 / Slaughter and primary processing 86 || |481/ Slaughter + primary processing lines 13

Lviv region. : Animal husbandry, poultry farming (equipment) 55 / Slaughter and primary processing 33 / | ||499Лінії забою + первинної переробки 6