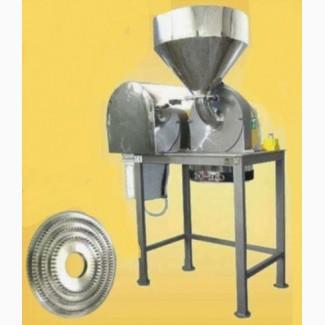

/ Agricultural machinery, equipment, inventory / Food industry (equipment) /Meat equipment / Various meat equipment + in assortment / Colloid mill type MUC (100-10000 kg/hour)...

For sale / buy

Colloid mill type MUC (100-10000 kg/hour) POLAND Olsha, Lviv region.

Price10 UAH.

Region: all of Ukraine,

Lviv region.

(Lviv)

Updated:

Description:

Mills consist of a hopper, a mill body in which a rotor is installed, a drive motor and a belt transmission installed on the table top. A cabinet with a plug is installed on the side of the table. A rim with a clamping strap is attached under the tabletop for fastening a bag for crushed products. There are two special bags on the equipment of the mill. Grinding of products consists in crushing their particles on rotating pins with a rotation speed of 5000 rpm, located along the perimeter of the rotor, and fixed pins located on the door of the mill. (work diagram nearby). The air taken by the mill together with the crushed products transports them and cools them at the same time. At the final stage of grinding, the air passes through the walls of the chamber, leaving crushed products in it.

At the request of the customer, the collection of crushed products can be carried out not only in a bag, but also in a tank or on a screw conveyor, and then in two bags alternately filled with crushed products.

Productivity [kg/h] Height [mm] Width [mm] Length [mm] Motor (400V) [kW]

300 1600 500 700 7.5

500 1650 600 900 11

1000 1800 700 1100 15

2000 2000 1000 1600 30

3000 2100 1100 1800 45

4000 2200 1200 2000 55

6000 2400 1300 2300 90

COLLOID MILL TYPE MUCD AND MUCDF (300-2000 KG / HOUR) POLAND

for grinding raw materials of the type: artificial, difficult to grind

The mill consists of a hopper, a mill body in which rotors, drive motors and a belt transmission are installed on the table top. On the side of the table there is a switch with so-called thermal protection to protect the motor from overload or phase interruption. A rim with a clamping strap is attached under the tabletop for fastening a bag for crushed products. The mill is equipped with two special packages. Grinding of products consists in crushing their particles on rotating pins with a rotation speed of 6000 rpm, located on the periphery of the rotor, and rotating pins in the opposite or the same direction with a speed of about 3000 rpm, located on a rotating disk installed in the door of the mill. The air sucked in by the mill together with the ground products cools them during the grinding process. At the final stage of grinding, the air passes through the walls of the bag, leaving crushed products in it.

Technical parameters:

Productivity [kg/h] Height [mm] Width [mm] Length [mm] Motor (400V) [kW]

300 1500 600 700 5.5/7.5

500 1650 700 900 7.5/11

1000 1800 1000 1100 11/15

2000 2000 1100 1600 15/30

COLLOID MILL LABORATORY MUCF AND MUKF POLAND

1. Description of construction and operation.

Grinding in a sieve mill consists in crushing the raw material sample on the teeth and blades on the rotor and the teeth on the lid of the grinder. An easily replaceable sieve around theworking wheel is installed for homogenization of milling (see the work diagram).

The mill is a rotary device with a rotor rotation frequency from 0 to 6000 rpm. Grinding of raw material samples on the bezite mill occurs as a result of the impact of the raw material particles on the rotating pins located on the rotor and on the solid pins located on the door cover, as well as as a result of the mutual collision of the particles (see the scheme of work).

The use of an inverter allows you to easily regulate the granulation of the product after grinding. At low rotor speeds, the product will be ground into coarse fractions, and at high rotor speeds, the product will be ground into "flour" fractions.

The carrier of crushed particles in both types ofshredders is air, which at the final stage of grinding feeds the crushed sample into the container under the shredder.

The air collected by the mill is also a cooling factor for crushed samples of raw materials.

2. Service description.

The meat grinder is equipped with a single-phase 220 V plug or a three-phase 380 V plug (depending on the size of the grinder), which must be inserted into the appropriate outlet in the workshop. To obtain a crushed sample, prepare the appropriate container, which is included in the shredder. This container is attached under the meat grinder.

Depending on the type of sample of crushed raw material and the required degree of its fragmentation, you should choose a suitable shredder: sifted or without a sieve.

Examples of the use of suitable grinders for suitable raw materials are given in the table. At the request of the customer, the laboratory mill can be easily replaced with a sieve and sieve.

The "Start-Stop" button turns on the grinder. After starting the grinder, the ground sample should be sent from the hopper to the grinding chamber by opening the latch installed at the outlet of the hopper, and the ground sample from the mill enters the container suspended below it.

Быстрая и тщательная очистка мельницы каждый раз после измельчения образцов сырья обеспечивает его конструкцию, без так называемой мертвые пространства с гладкими и округлыми поверхностями.

The meat grinder is equipped with an electric lock that prevents the grinder from starting when the door is open.(//tractor-service.com)

The mill is certified by the National Institute of Hygiene in Warsaw.

Selection of the grinding component according to the type of ground raw material.

Type of raw material Type of rotor and sieve

spices

Cereals

corn

Coal / lignite

Activated charcoal

sugar

salt

Tablets and powders

pharmaceutical preparations

rhizome

Kory

root crops

leaves

Petals of flowers

Straw, grass

A rotor with the right number of blades and teeth for the sample, with a sieve built around the engine. The required degree of grinding is achieved by selecting the appropriate screen and rotor speed.

fruits

casein

rapeseed

Milk powder

gypsum

talc

dolomite

breadcrumbs Needle rotor (sieveless); The degree of grinding depends on the number and density of the dowel seat and the choice of the appropriate rotation speed.

Technical parameters (1)

Wydajność [g/15sek] Wysokość [mm] Szerokość [mm] Dlugość [mm] Ciężar [kg] Silnik (400V) [kW] Silnik (400V) [obr/min]

100 400 300 350 35 1.2 3000 - 18000

• Hopper capacity: 1.5 dm

• Capacity of the suspended container: 0.5 dm

Technical parameters (2)

Wydajnosc [kg/1.5min] Wysokosc [mm] Szerokosc [mm] Dlugosc [mm] Ciezar [kg] Silnik (400V) [kW] Silnik (400V) [obr/min]

1 900 400 500 60 3.0 2880

• Hopper capacity: 6 dm

• Hanging container capacity: 6 dm

Mills consist of a hopper, a mill body in which a rotor is installed, a drive motor and a belt transmission installed on the table top. A cabinet with a plug is installed on the side of the table. A rim with a clamping strap is attached under the tabletop for fastening a bag for crushed products. There are two special bags on the equipment of the mill. Grinding of products consists in crushing their particles on rotating pins with a rotation speed of 5000 rpm, located along the perimeter of the rotor, and fixed pins located on the door of the mill. (work diagram nearby). The air taken by the mill together with the crushed products transports them and cools them at the same time. At the final stage of grinding, the air passes through the walls of the chamber, leaving crushed products in it.

At the request of the customer, the collection of crushed products can be carried out not only in a bag, but also in a tank or on a screw conveyor, and then in two bags alternately filled with crushed products.

Productivity [kg/h] Height [mm] Width [mm] Length [mm] Motor (400V) [kW]

300 1600 500 700 7.5

500 1650 600 900 11

1000 1800 700 1100 15

2000 2000 1000 1600 30

3000 2100 1100 1800 45

4000 2200 1200 2000 55

6000 2400 1300 2300 90

COLLOID MILL TYPE MUCD AND MUCDF (300-2000 KG / HOUR) POLAND

for grinding raw materials of the type: artificial, difficult to grind

The mill consists of a hopper, a mill body in which rotors, drive motors and a belt transmission are installed on the table top. On the side of the table there is a switch with so-called thermal protection to protect the motor from overload or phase interruption. A rim with a clamping strap is attached under the tabletop for fastening a bag for crushed products. The mill is equipped with two special packages. Grinding of products consists in crushing their particles on rotating pins with a rotation speed of 6000 rpm, located on the periphery of the rotor, and rotating pins in the opposite or the same direction with a speed of about 3000 rpm, located on a rotating disk installed in the door of the mill. The air sucked in by the mill together with the ground products cools them during the grinding process. At the final stage of grinding, the air passes through the walls of the bag, leaving crushed products in it.

Technical parameters:

Productivity [kg/h] Height [mm] Width [mm] Length [mm] Motor (400V) [kW]

300 1500 600 700 5.5/7.5

500 1650 700 900 7.5/11

1000 1800 1000 1100 11/15

2000 2000 1100 1600 15/30

COLLOID MILL LABORATORY MUCF AND MUKF POLAND

1. Description of construction and operation.

Grinding in a sieve mill consists in crushing the raw material sample on the teeth and blades on the rotor and the teeth on the lid of the grinder. An easily replaceable sieve around theworking wheel is installed for homogenization of milling (see the work diagram).

The mill is a rotary device with a rotor rotation frequency from 0 to 6000 rpm. Grinding of raw material samples on the bezite mill occurs as a result of the impact of the raw material particles on the rotating pins located on the rotor and on the solid pins located on the door cover, as well as as a result of the mutual collision of the particles (see the scheme of work).

The use of an inverter allows you to easily regulate the granulation of the product after grinding. At low rotor speeds, the product will be ground into coarse fractions, and at high rotor speeds, the product will be ground into "flour" fractions.

The carrier of crushed particles in both types ofshredders is air, which at the final stage of grinding feeds the crushed sample into the container under the shredder.

The air collected by the mill is also a cooling factor for crushed samples of raw materials.

2. Service description.

The meat grinder is equipped with a single-phase 220 V plug or a three-phase 380 V plug (depending on the size of the grinder), which must be inserted into the appropriate outlet in the workshop. To obtain a crushed sample, prepare the appropriate container, which is included in the shredder. This container is attached under the meat grinder.

Depending on the type of sample of crushed raw material and the required degree of its fragmentation, you should choose a suitable shredder: sifted or without a sieve.

Examples of the use of suitable grinders for suitable raw materials are given in the table. At the request of the customer, the laboratory mill can be easily replaced with a sieve and sieve.

The "Start-Stop" button turns on the grinder. After starting the grinder, the ground sample should be sent from the hopper to the grinding chamber by opening the latch installed at the outlet of the hopper, and the ground sample from the mill enters the container suspended below it.

Быстрая и тщательная очистка мельницы каждый раз после измельчения образцов сырья обеспечивает его конструкцию, без так называемой мертвые пространства с гладкими и округлыми поверхностями.

The meat grinder is equipped with an electric lock that prevents the grinder from starting when the door is open.(//tractor-service.com)

The mill is certified by the National Institute of Hygiene in Warsaw.

Selection of the grinding component according to the type of ground raw material.

Type of raw material Type of rotor and sieve

spices

Cereals

corn

Coal / lignite

Activated charcoal

sugar

salt

Tablets and powders

pharmaceutical preparations

rhizome

Kory

root crops

leaves

Petals of flowers

Straw, grass

A rotor with the right number of blades and teeth for the sample, with a sieve built around the engine. The required degree of grinding is achieved by selecting the appropriate screen and rotor speed.

fruits

casein

rapeseed

Milk powder

gypsum

talc

dolomite

breadcrumbs Needle rotor (sieveless); The degree of grinding depends on the number and density of the dowel seat and the choice of the appropriate rotation speed.

Technical parameters (1)

Wydajność [g/15sek] Wysokość [mm] Szerokość [mm] Dlugość [mm] Ciężar [kg] Silnik (400V) [kW] Silnik (400V) [obr/min]

100 400 300 350 35 1.2 3000 - 18000

• Hopper capacity: 1.5 dm

• Capacity of the suspended container: 0.5 dm

Technical parameters (2)

Wydajnosc [kg/1.5min] Wysokosc [mm] Szerokosc [mm] Dlugosc [mm] Ciezar [kg] Silnik (400V) [kW] Silnik (400V) [obr/min]

1 900 400 500 60 3.0 2880

• Hopper capacity: 6 dm

• Hanging container capacity: 6 dm

|

Author, contacts | |

Velmark M/ reviews info. / activity evaluation | |

|

Phone:

+38(xxxxxx

show

| |

| Skype: vlad013 | |

| http://www.wellmarkm.net | |

| facebook.com/wellmarkm | |

All user ads ~87 | |

Ad ID: #1000382

(Added by registered user, registration date: 2013-07-21)

Added / Updated: 03- 09-2024 10:44 (current, until: 03-09-2025)

Permanent Ad Address:

Impressions / views for today: ?, total: ?

Similar ads

There are many interesting...

Total255 similar adsin the heading "Meat equipment"

All Ukraine: Food industry (equipment) 1524 / Meat equipment 255 / | ||456Різне м`ясне обладнання + в асортименті 51

Lviv region:Food industry ( equipment) 132 / Meat equipment 50 / Various meat equipment + in assortment 26