Ground equipment for monitoring crops by color for the organization of differentiated application of fertilizers. the surrounding environment and, in particular, reservoirs, surface groundwater.

Високі ціни на добрива та питання їх раціонального використання завжди є актуальними, в тому числі для запобігання екологічні проблеми неконтрольованого потрапляння нітратів в оточуююче середовище і зокрема водойми, поверхневі підземні води.

Specialized equipment that performs non-contact operational assessment of the state ofnitrogen nutrition for the organization differentiated application of fertilizers.

Differentiatedapplication of fertilizers, - provides that fertilizers are applied selectively, where the need for certain fertilizers is particularly urgent. Moreover, two main methods are used: application in real time and application from a previously prepared map of the field.

The principle of operation of such equipment will be explained on the example of wheat, which needs to be fertilized several times during its growing season.

One of the main stages of feeding is the stage of "coming into the tube". The picture shows a photo in the optical range of a hospital for studying fertilizer application systems at this stage of vegetation.

Analyzing the image, we see that the area near the road (on the left) has not been fertilized for years. After that, there are 5 more plots where fertilizers were applied with increasing concentration, while 150% of the recommended dose of nitrogen fertilizers was already applied to the last of the 5 plots. In the future, to check the results (organization of repetition of experiments), the dosage of fertilizers is again reduced to zero. Closer to the road, the color of the plants has a light green shade, which turns into emerald as the dose of fertilizers increases. That is, color is an informative parameter.

This phenomenon is well known to agronomists, and a qualified specialist can determine the required amount of fertilizers with sufficient accuracy. The question remains - where to get such qualified specialists en masse?

A possible option is consulting services, when specialists are invited in case of need or even receive consultations remotely. The development of the Internet and digital photography have greatly simplified manufacturers' access to databases for sheet diagnostics. Now it is enough to take a picture and contact the appropriate site, where consultations are provided due to the involvement of experts and machine learning technologies.

There are both paid and free products on the domestic market, albeit with rather limited functionality. As an example, the service Helping Plants A (http://az.4androidapk.com/developer/qvet) and Yara CheckIT (https:// www.yara.ua/) are free and work in offline mode, and the use of one of the applications of the Dinut software series (for different cultures) is paid.

Such services are primarily intended for diagnosing plant diseases and identifying pests, although issues of mineral nutrition are also diagnosed to a certain extent - a general indication of a lack or excess of a nutrient element. The indicator rather than the measuring mode is primarily explained by the complexity of the organization of lighting correction.

However, for industrial equipment, such measurements are quite possible, both with purely natural lighting and with the use of special lamps. Differentiated application of fertilizers can be carried out both by controlling the supply of the reagent and by controlling the speed of movement of the equipment on the field. Both technologies have their advantages and disadvantages. Thus, when controlling bandwidth, it is possible to increase selectivity, when the amount of application is selected individually for each of the field strips. However, this limits the nomenclature of fertilizers to a certain extent, since when the pressure changes with colloidal solutions, characteristic of fertilizers, incorrect application of the active substance is possible. Speed control is technically easier to organize and even automate in existing aggregate motion control systems.

There are several manufacturers of such serial equipment on the Ukrainian market:

GreenSeeker

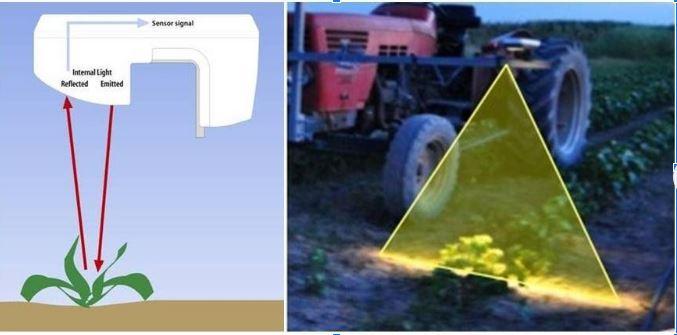

GreenSeeker of the company Trimble Agriculture (USA) has both a purely measuring system and a specialized complex designed for differentiated fertilization based on from the value of the NVDI index. To increase the selectivity of the received data, it is possible to install several measuring units in parallel. The on-board system can use its own light source for each measurement channel, so it can work both during daylight hours and at night.

GreenSeeker Spectral Sensor System, a schematic of the device and a photograph of the kit in use at dusk.

CropSpec

One of the companies working in the field of optical sensor systems Topcon Positioning Systems (Japan), in cooperation with Yara International, created a system for optical diagnostics of nitrogen supply to plants based on the CropSpec sensor. The Topcon system uses two sensors, one on each side of the complex to measure the spectral characteristics of the crop - the NDVI index

The CropSpec sensor is designed to measure the state of nitrogen nutrition of plants.

Just like the previous sample, the system has its own radiation source to ensure 24-hour operation.

Crop Circle ACS- 430

Another technical means for implementing the technology of variable rationing of fertilizers is the optical sensor Holland Scientific Crop Circle ACS-430 (USA). It also belongs to the group of active sensors, and has its own light source (LED) and a three-channel silicon detector with a spectral range of 320-1100 nm.

Crop Circle Sensor ACS-470

The optical system includes three optical measurement channels, which allows the user to work with several wavelengths, nm: 450, 550, 650, 670, 730, 800. Multiple stress indices (NDVI, SRI, etc.) can be used, allowing the complex to be used to quantify the impact of nutrients, plant moisture, detect plant diseases or other signs of stress.

CropSensor

The OptRx optical sensor is the next generation of these devices from Holland Scientific, built on the experience and development of Crop Circle operation. It is sold under the AG Leader brand under the name CropSensor. The OptRx-based implementation of variable fertilizer rationing technology uses the same calibration dependence parameters as for the previous generation sensors.

The OptRx sensor, mounted on the base of the fertilizer application equipment

N-sensor

One of the first industrial means of optical diagnostics is the N-sensor produced by Yara International (Norway). This is a passive optical system consisting of four photomatrices that determine the intensity of reflected sunlight and one zenith photocell to determine the intensity of sunlight in the wavelength range of 660-800 nm.

Yara N-Sensor|| |182

Фотоелементи поєднані з обчислювальним блоком та видають сигнал для управління роботою розкидача мінеральних добрив. На початку роботи обирають ділянку посіву, характерну для загальної площі, та проводять калібрування сенсорів, за яким встановлюють середню інтенсивність відбитого світла та відповідну дозу азотних добрив (у фізичній масі). Наступна операція (робочий режим) – відбуваються вимірювання інтенсивності відбитого світла та синтез отриманої інформації, що передається на засоби управління роботою розкидача. Недоліком цього комплексу є те, що джерелом світла є сонце, тому час роботи обмежується 10-12 годинами впродовж доби.

In summary..

These technologies can save the economy money due to rational use fertilizers and ensure appropriate grain quality. However, such equipment requires methodical support, namely calibration dependencies between the state of nitrogen supply and spectral indicators. This will be served by the creation of own stationary experiments on the use of fertilizer systems, on which to calibrate the equipment.

The existing nomenclature of serial equipment shows that these technologies are already the realities of the present, and not a fantastic future. They are able to save the economy money due to the rational use of fertilizers and ensure the appropriate quality of grain. However, such equipment also needs a certain methodical support.

Unfortunately, the centralized state methodological support is insufficient, and ready-made calibration dependencies between the state of nitrogen supply and spectral indicators are insufficient. However, farms are capable of creating such dependencies themselves. As an example, - the creation of own stationary experiments on the use of fertilizer systems, on which to carry out equipment calibration. This approach is also used abroad, when the company selects for itself the optimal fertilizers in terms of availability and cost. Gradually, the farm accumulates its own data bank both in terms of calibration dependencies and digital field maps, which are extremely useful for agricultural practices.

Thus, despite the increasingly advanced auxiliary equipment, the agronomist will not be left without work.|| |193

Natalya Anatoliivna Pasichnyk (n.pasichnyk@nubip.edu.ua)