/ Agricultural services / Repair of farm. technics, equipment / Repair of various agricultural buildings techniques, equipment + in assortment / Dynamic and static balancing of rotors...

I provide a service

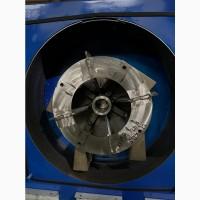

Dynamic and static balancing of combine rotors, crushers, flywheels , Poltava region.

Price1200 UAH.

Region:all of Ukraine, || |153

Полтавская обл.

Updated:

Company Bioecoprom GK provides services for dynamic and static balancing of rotors for a wide range of industrial equipment. Our services are critical to maintaining optimal machine performance and reducing risks associated with vibration and wear.

Application of balancing rotors:

Rotor balancing is a fundamental process for the following types of equipment and units:

Industrialcrushers: Includes jaw crushers, cone crushers, hammer crushers, and rotary crushers used to crush rock, metal, and other hard materials.

Flywheels: Used in the automotive industry and in the production of power systems to balance and smooth the rotation of shafts.

Harvester rotors: Key elements of agricultural machines that require precise balancing for efficient and safe operation under time of harvest periods.(//tractor-service.com)

Ventilation system rotors: Used in air conditioning, extraction and aspiration systems to ensure uniform and effective air exchange.

Centrifuges and pumps: These units are used in the chemical, pharmaceutical, food and water treatment industries to separate liquids and suspensions.

Benefits of balancing with Bioecopro GK:

Improved equipment performance: Balancing rotors reduces vibration, wear and heat stress, extending machine life.

Lower operating costs: Properly balanced equipment consumes less energy and requires fewer repairs.

Increased work safety: Minimizing vibration helps prevent accidents and breakdowns during work.

Individual approach: Our specialists develop balancing solutions based on the specific needs and characteristics of each client.

Bioecoprom GC uses advanced technologies and equipment to provide balancing services at the highest level. Our specialists undergo regular training and certification to ensure the best result for each project. Choosing Bioekoprom, you choose reliability, quality and professionalism.

Application of balancing rotors:

Rotor balancing is a fundamental process for the following types of equipment and units:

Industrialcrushers: Includes jaw crushers, cone crushers, hammer crushers, and rotary crushers used to crush rock, metal, and other hard materials.

Flywheels: Used in the automotive industry and in the production of power systems to balance and smooth the rotation of shafts.

Harvester rotors: Key elements of agricultural machines that require precise balancing for efficient and safe operation under time of harvest periods.(//tractor-service.com)

Ventilation system rotors: Used in air conditioning, extraction and aspiration systems to ensure uniform and effective air exchange.

Centrifuges and pumps: These units are used in the chemical, pharmaceutical, food and water treatment industries to separate liquids and suspensions.

Benefits of balancing with Bioecopro GK:

Improved equipment performance: Balancing rotors reduces vibration, wear and heat stress, extending machine life.

Lower operating costs: Properly balanced equipment consumes less energy and requires fewer repairs.

Increased work safety: Minimizing vibration helps prevent accidents and breakdowns during work.

Individual approach: Our specialists develop balancing solutions based on the specific needs and characteristics of each client.

Bioecoprom GC uses advanced technologies and equipment to provide balancing services at the highest level. Our specialists undergo regular training and certification to ensure the best result for each project. Choosing Bioekoprom, you choose reliability, quality and professionalism.

|

Store, contacts | |

Evheny Nikolaevich / отзывы, инфо. / activity assessment | |

|

Phone:

+38( xxxxxx. //www.bioekoprom.com.ua

показать

| |

| Skype: Mardukk1 | |

| http://www.bioekoprom.com.ua | |

All user ads ~217 | |

Ad ID: #1300217

(added by a registered user, registration date: 19-12-2015)

Added/Updated: 27- 09-2024 11:49 (current, until: 09-27-2025)

Permanent ad address:

Showed / watched for today: ?, total: ?

Similar ads

Among them there are many interesting...

All Ukraine : Agricultural services 6482 / | ||411Ремонт с.х. техники, оборудования 2366 / Repair of various .х. technics, equipment + in assortment 515

Poltava region: Services for agriculture 250 / Repair of farm house technics, equipment 94 / Repair of various .х. technics, equipment + in assortment 63