/ Agricultural equipment, equipment, inventory / Spare parts for agricultural machinery / Spare parts for machinery post-harvest processing / Spare parts for conveyors / Mechanical connectors of RSHM (similar to Vulkan Krug...

Sell / buy

Mechanical connectors RShM (analog Vulkan Krug, PVS-1), Kharkiv region.

Price5800 UAH.

Region:all of Ukraine,

Kharkov region.

(Https://youtu.be/U75qtHt_3tQ)

Updated:

Mechanical connectors RSHM for loaded conveyor belts (production and extraction of granite, clay, sand, production of concrete, building materials)

emergency docking of the conveyor belt

longitudinal cut

transverse cut

tape failure caused by falling material or mechanical damage.

layering of vulcanized and glued butt joints

RSHM mechanical connectors for joining and repairing conveyor belts

HOW MUCH DOES IT COST TO CONNECT A CONVEYOR BELT WITH MECHANICAL CONNECTORS?

With the minimum scheme for belts with a light load: conveyor belt with a width of 1000 mm = 42 pcs. RSHM mechanical connectors (in two rows). For details, see the specifications.

ASSEMBLY INSTRUCTIONS

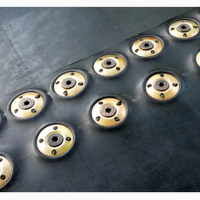

RSM mechanical connectors are intended for connecting conveyor belts operated in quarries, mines, mines and beneficiation factories, both with normal and difficult operating conditions. The mechanical butt joint of the RSHM has a round profiled shape of pressure plates with perforation elements. The RSHM butt joint element consists of two pressure perforated washers with through holes and a connecting screw. A nut is pressed into the lower perforated washer.

The principle of operation of the mechanical connection of the RSHM consists in providing the calculated force of compression of the tape web with screws at the joint with the help of upper and lower pressure perforated washers installed in a certain order acting on the connected ends of the tape web with a stepped separation. Due to the concave design of the washers, when tightening and immersing the connection elements into the body of the belt web, it allows the rubber coating to be evenly distributed under it. Perforation elements on pressure washers ensure the output of excessrubbers iz otverstyy, thereby allowing to maximally immerse the connection elements in the coating of the tape cloth. The special shape of the lower part of the ribs prevents the effect of cutting through the lining. Depending on the strength of the conveyor belt, the load and the length of the conveyor, various docking options are recommended, according to the diagrams given.(//tractor-service.com)

The minimum thickness of the conveyor belt is 8 mm.

The recommended minimum diameter of the drive drum is 350 mm* *

*if the drive drum has a smaller diameter, please contact our specialists for consultation.

* for one- and two-row docking schemes, the minimum diameter of the drive drum is 250 mm.

* strong docking schemes are offered for highly loaded tapes

INSTALLATION TOOL

To install the connectors, it is recommended to use a special tool - narrow and wide templates, a special knife, a special key, a breaker, pliers, a winding plug, a rotator, a battery screwdriver (for general industrial use). The use of a standard set of tools significantly reduces the installation time, however, it is possible to perform the connection even without templates, by marking out the tape cloth manually according to the given diagrams. The instrument can be ordered in a set or in parts.

INFORMATION FOR CHOOSING A CONNECTION SCHEME

Depending on the strength of the conveyor belt, the load and the length of the conveyor, various stitching options are recommended: the most durable, consisting of seven rows for belts with a strength of up to 1600 N/mm, a standard joint of five rows of connectors for belts with a strength of up to 1250 N/mm, as well as a special, ten-row joint for web connections with a strength of up to 2500 N/mm (according to the diagrams installations).

For tapes with a load of up to 630/mm - 800 N/mm on auxiliary or not long conveyors, one- and two-row docking schemes are offered.

IMPORTANT! It is not allowed to cross the canvas with parallel rows of connectors in one plane.

IMPORTANT! The maximum strength of the butt joint is reached when the screws are tightened with a torque of at least 150 N/m.

Sets of 120 pcs., 200 pcs., 276 pcs.

emergency docking of the conveyor belt

longitudinal cut

transverse cut

tape failure caused by falling material or mechanical damage.

layering of vulcanized and glued butt joints

RSHM mechanical connectors for joining and repairing conveyor belts

HOW MUCH DOES IT COST TO CONNECT A CONVEYOR BELT WITH MECHANICAL CONNECTORS?

With the minimum scheme for belts with a light load: conveyor belt with a width of 1000 mm = 42 pcs. RSHM mechanical connectors (in two rows). For details, see the specifications.

ASSEMBLY INSTRUCTIONS

RSM mechanical connectors are intended for connecting conveyor belts operated in quarries, mines, mines and beneficiation factories, both with normal and difficult operating conditions. The mechanical butt joint of the RSHM has a round profiled shape of pressure plates with perforation elements. The RSHM butt joint element consists of two pressure perforated washers with through holes and a connecting screw. A nut is pressed into the lower perforated washer.

The principle of operation of the mechanical connection of the RSHM consists in providing the calculated force of compression of the tape web with screws at the joint with the help of upper and lower pressure perforated washers installed in a certain order acting on the connected ends of the tape web with a stepped separation. Due to the concave design of the washers, when tightening and immersing the connection elements into the body of the belt web, it allows the rubber coating to be evenly distributed under it. Perforation elements on pressure washers ensure the output of excessrubbers iz otverstyy, thereby allowing to maximally immerse the connection elements in the coating of the tape cloth. The special shape of the lower part of the ribs prevents the effect of cutting through the lining. Depending on the strength of the conveyor belt, the load and the length of the conveyor, various docking options are recommended, according to the diagrams given.(//tractor-service.com)

The minimum thickness of the conveyor belt is 8 mm.

The recommended minimum diameter of the drive drum is 350 mm* *

*if the drive drum has a smaller diameter, please contact our specialists for consultation.

* for one- and two-row docking schemes, the minimum diameter of the drive drum is 250 mm.

* strong docking schemes are offered for highly loaded tapes

INSTALLATION TOOL

To install the connectors, it is recommended to use a special tool - narrow and wide templates, a special knife, a special key, a breaker, pliers, a winding plug, a rotator, a battery screwdriver (for general industrial use). The use of a standard set of tools significantly reduces the installation time, however, it is possible to perform the connection even without templates, by marking out the tape cloth manually according to the given diagrams. The instrument can be ordered in a set or in parts.

INFORMATION FOR CHOOSING A CONNECTION SCHEME

Depending on the strength of the conveyor belt, the load and the length of the conveyor, various stitching options are recommended: the most durable, consisting of seven rows for belts with a strength of up to 1600 N/mm, a standard joint of five rows of connectors for belts with a strength of up to 1250 N/mm, as well as a special, ten-row joint for web connections with a strength of up to 2500 N/mm (according to the diagrams installations).

For tapes with a load of up to 630/mm - 800 N/mm on auxiliary or not long conveyors, one- and two-row docking schemes are offered.

IMPORTANT! It is not allowed to cross the canvas with parallel rows of connectors in one plane.

IMPORTANT! The maximum strength of the butt joint is reached when the screws are tightened with a torque of at least 150 N/m.

Sets of 120 pcs., 200 pcs., 276 pcs.

|

Shop, contacts | |

Leonid Chepurny / отзывы, информация / activity evaluation | |

|

Phone:

+380xxxxxx

show

| |

All user ads ~24 | |

Ad ID: #1113464

(added by a registered user, registration date: 04-20-2021)

Added / Updated: 12-27-2025 15:26 (current, until: 12-27-2026)

Permanent ad address:

Showed / watched for today: ?, total: ?

Similar ads

Among them there are many interesting...

All Ukraine: Spare parts for agricultural machinery 19037 / Spare parts for post-harvest machinery processing 901 / Spare parts for transporters 197

Kharkiv region: Spare parts for agricultural machinery 4802 / Spare parts for machinery for post-harvest processing 30 / Spare parts for to transporters 23